The Big Kids Table was developed in Materiality, a course focused on appreciating the materiality of wood and hands-on manufacturing.

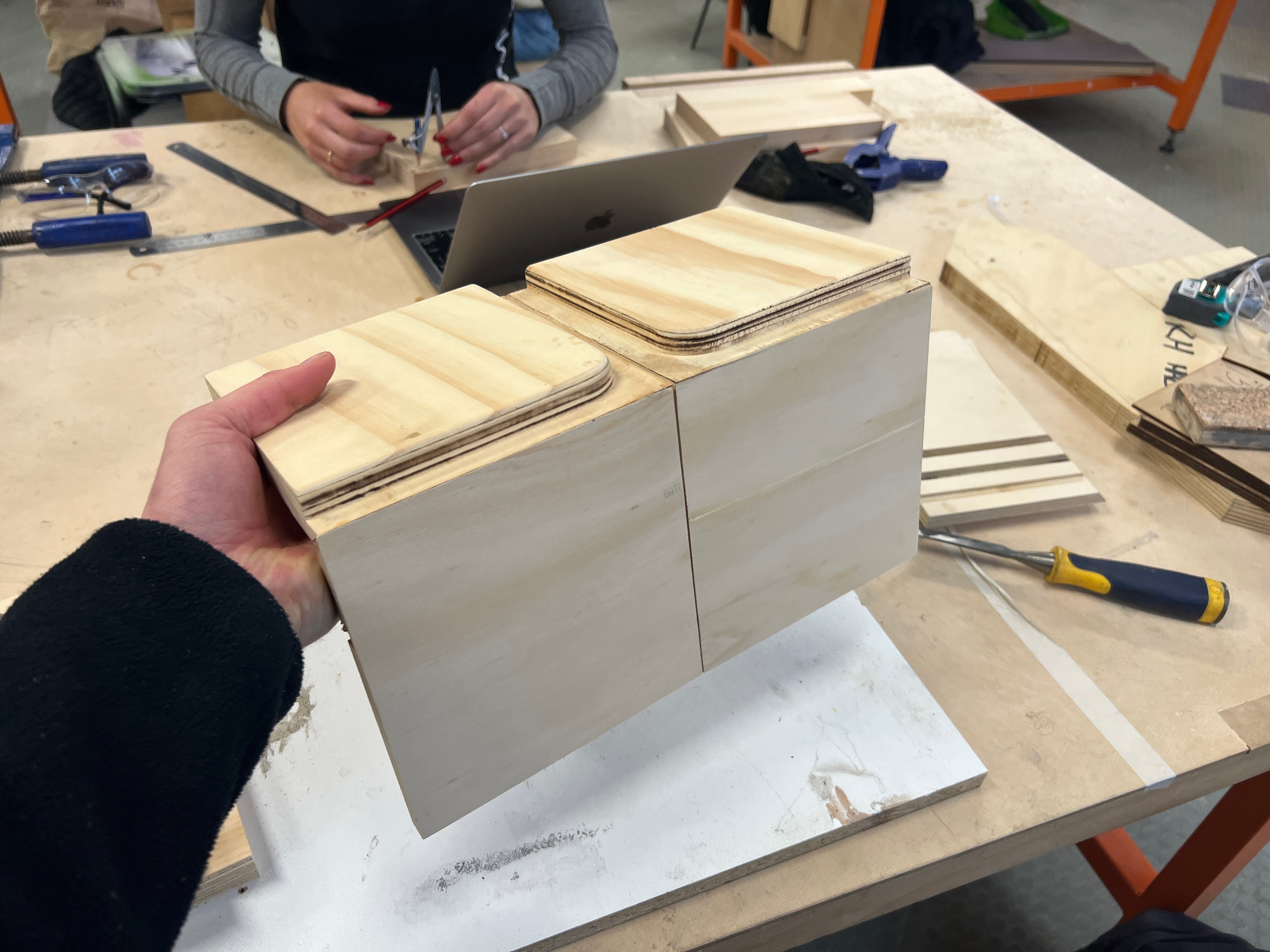

My design centres on modular storage units that magnetically snap together, combining precision joinery with a playful form. The form is inspired by the building blocks a child might play with, with the goal of bringing a sense of play into an adult’s living room through interaction with the object.

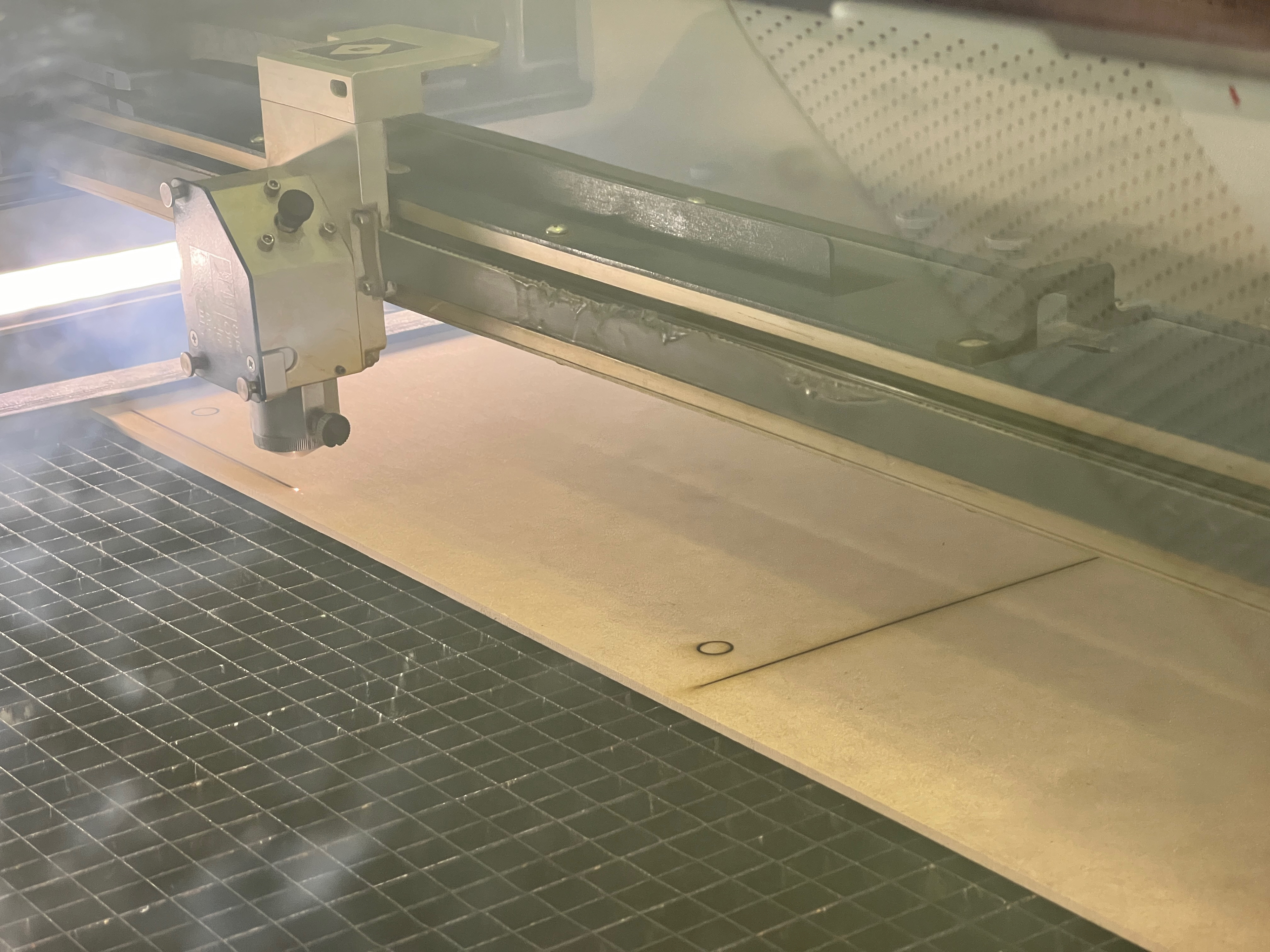

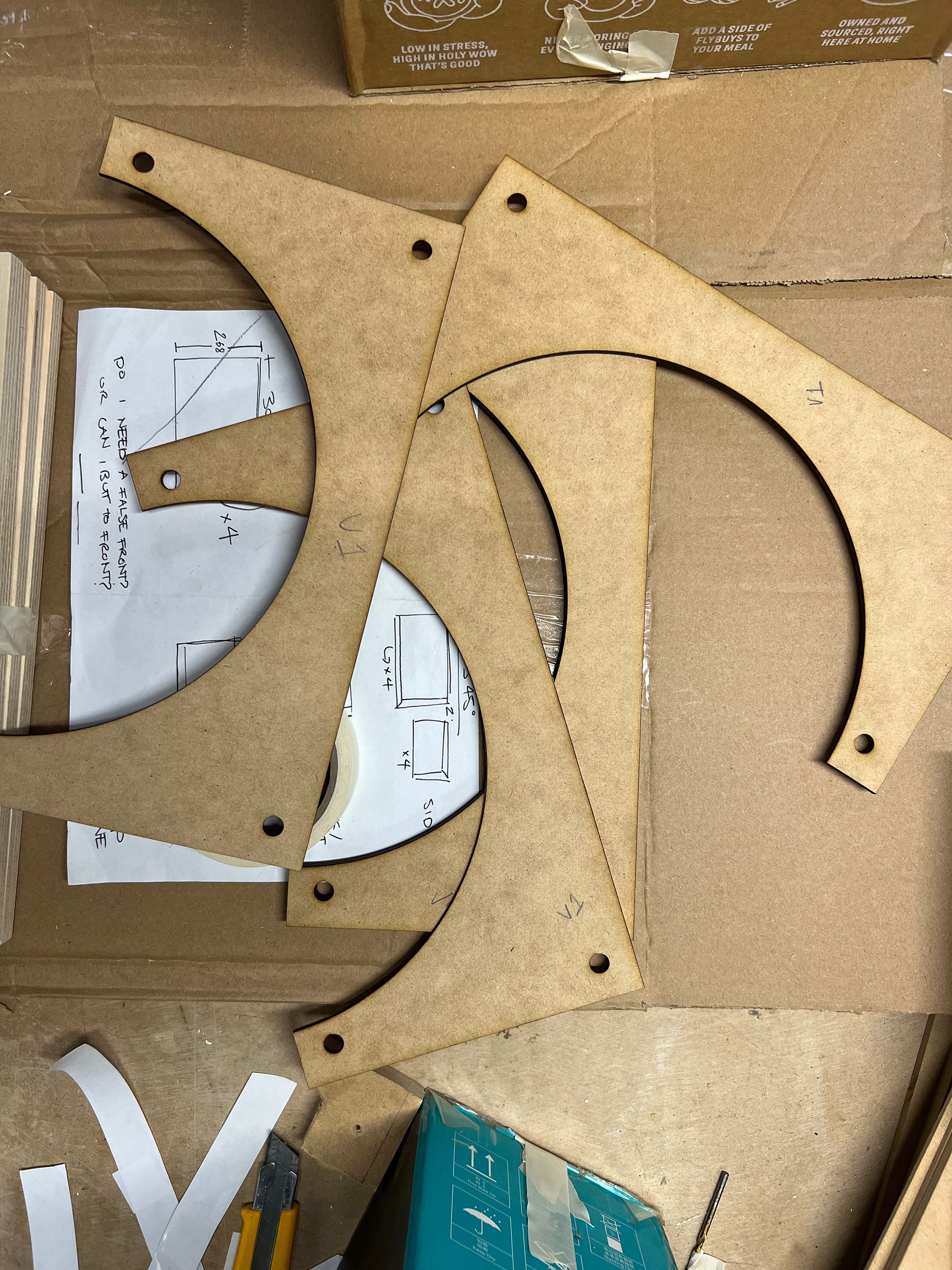

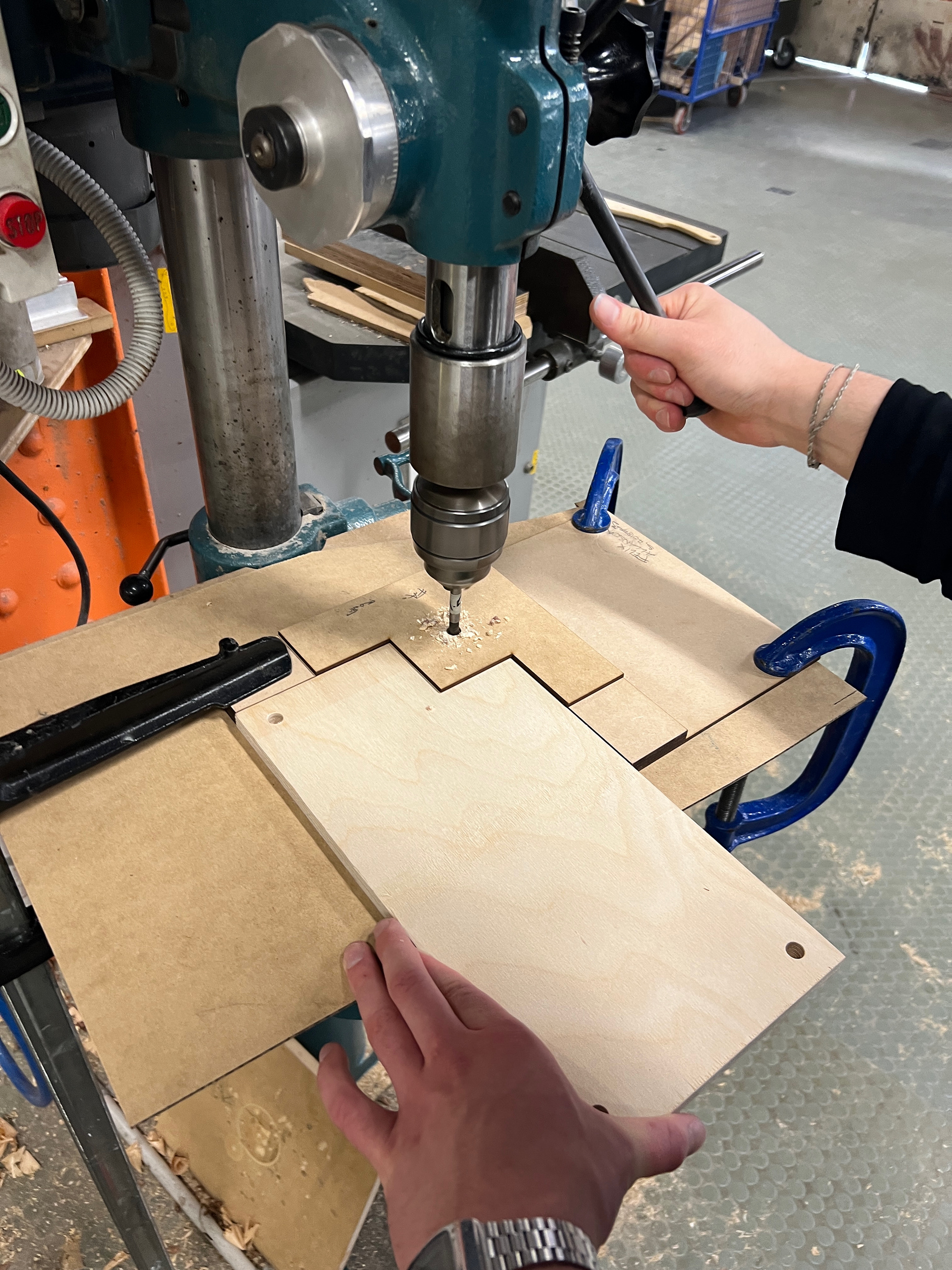

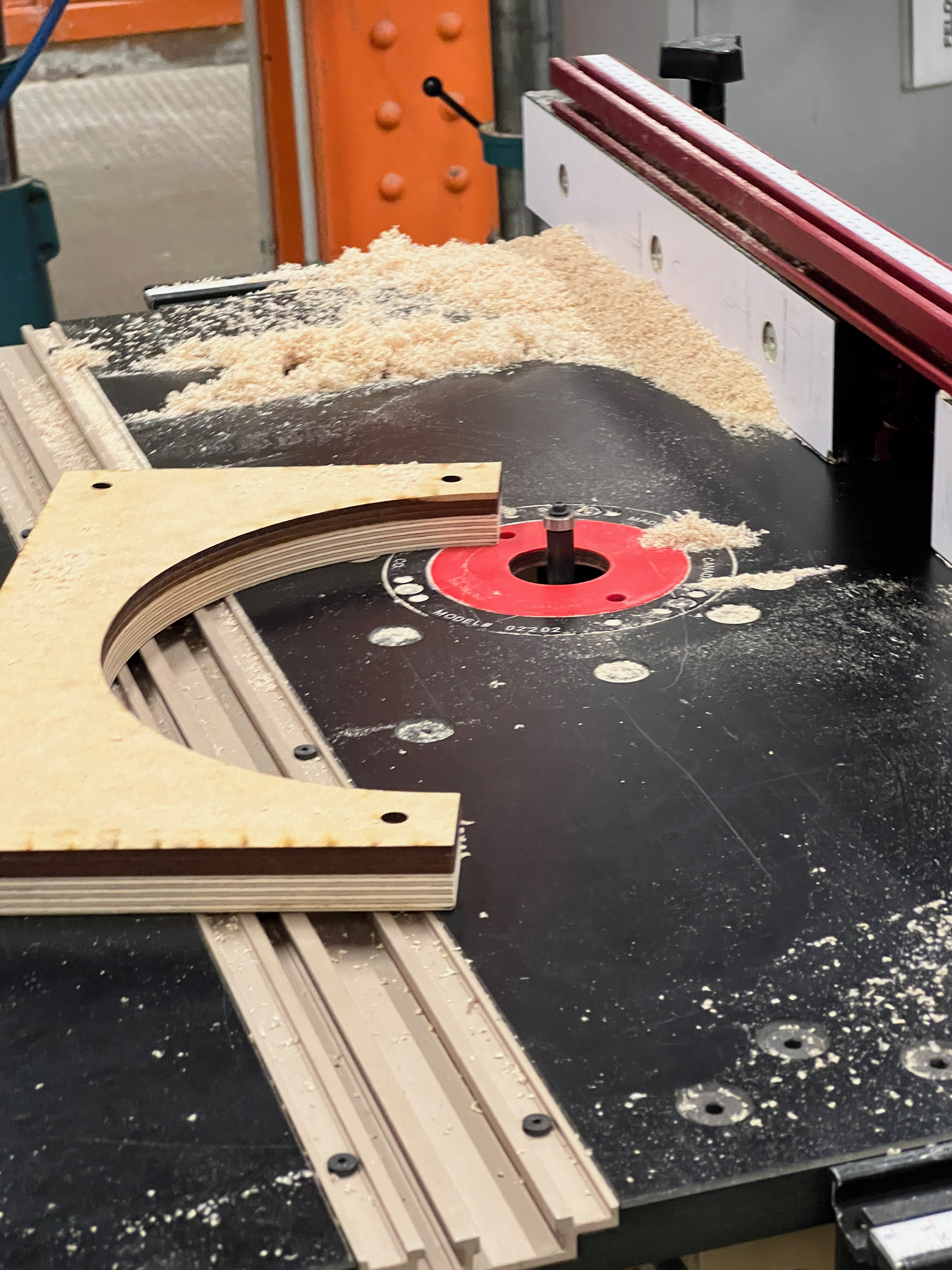

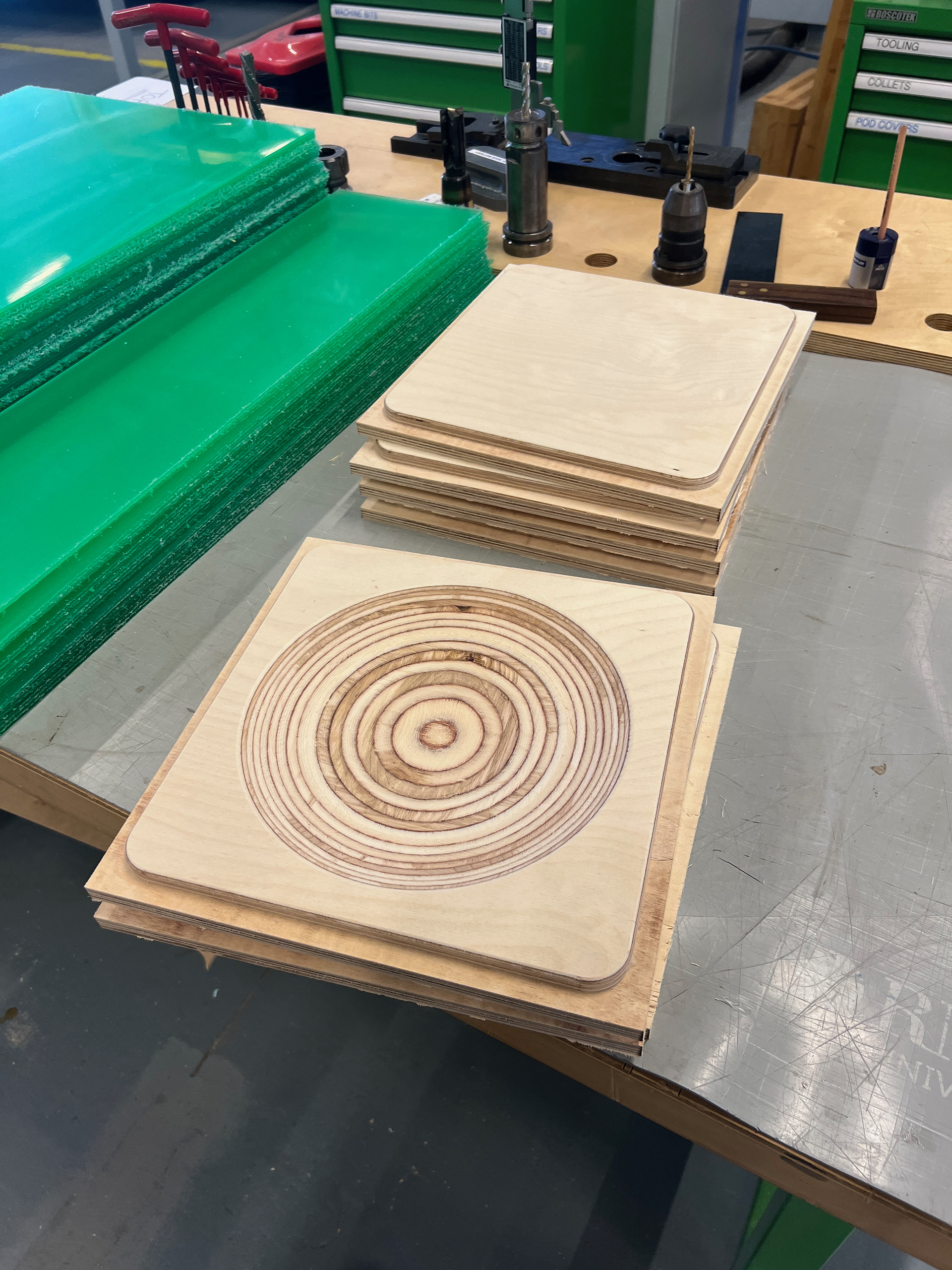

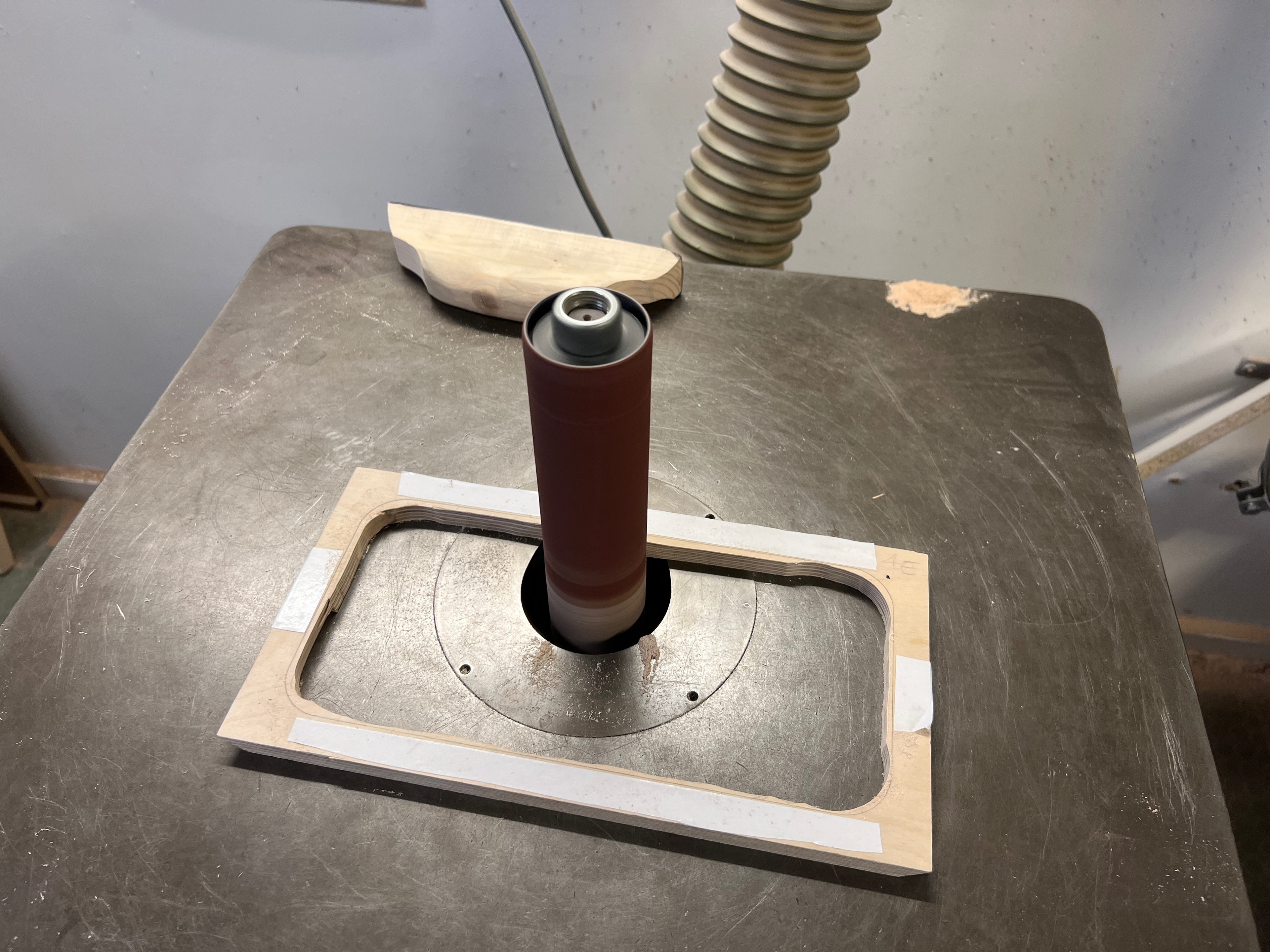

The process involved extensive planning, model making, cutting lists, nesting, CNC milling, lamination, jig-making, and finishing. Working through sourcing issues, magnet orientation errors, and tight tolerances sharpened my problem-solving skills and deepened my understanding of modularity and repeatable systems.

This project reflects my evolving approach to practical design: intentional, resourceful, and grounded in a clear vision carried through to physical execution.

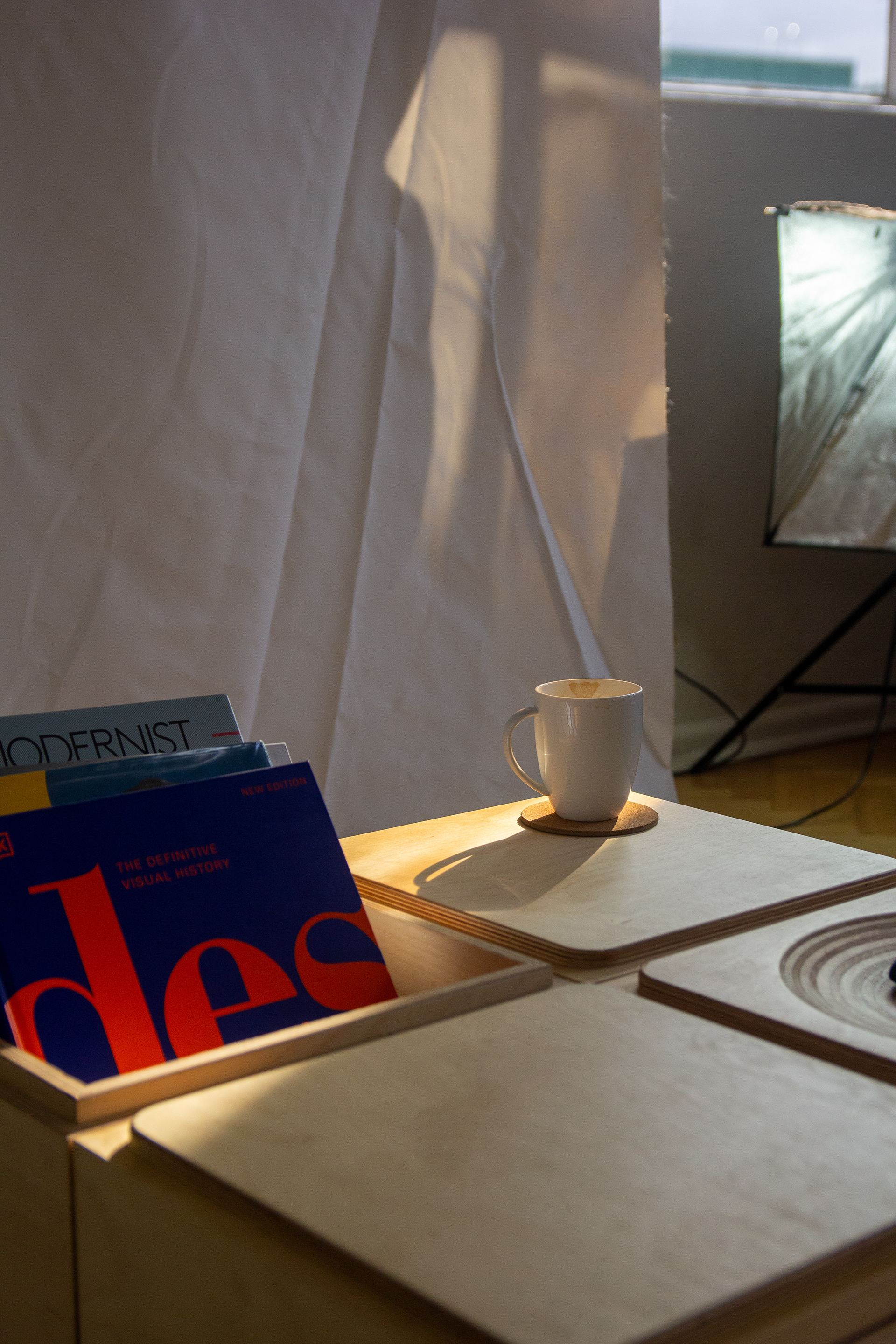

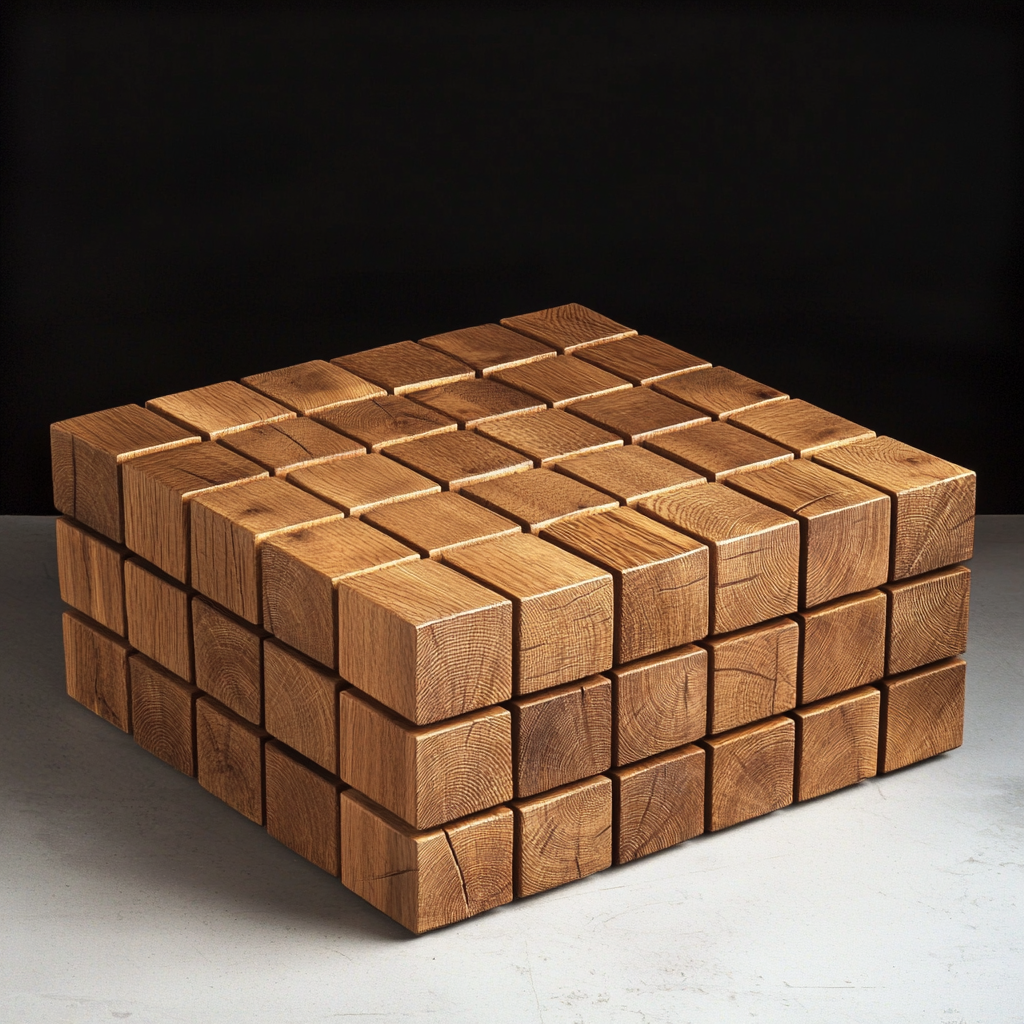

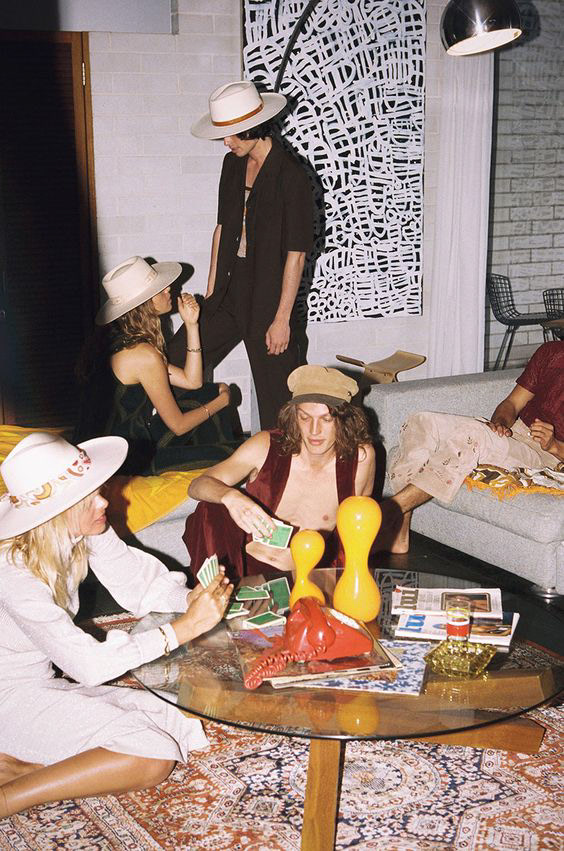

Mood Board, Prompt: "Memory"

My chosen memory was play, with LEGO and my family. That feeling of freedom and discovery through play is core to childhood, but easily lost as we grow up. I wanted to recapture that spirit and inject it into a living room object: something modular, playful, and social. The form nods to building blocks, inviting hands-on exploration in a space already shaped by interaction and games.

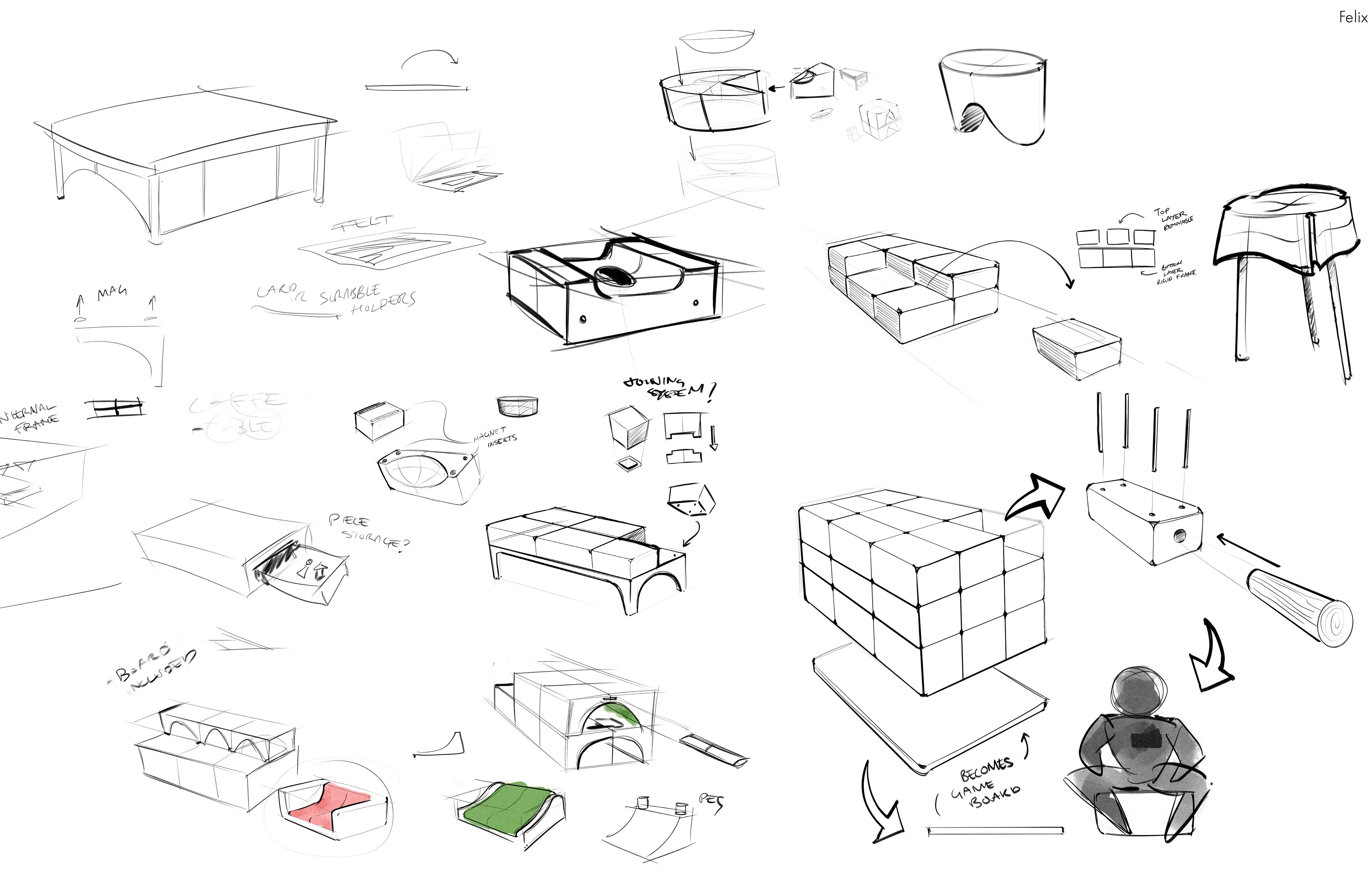

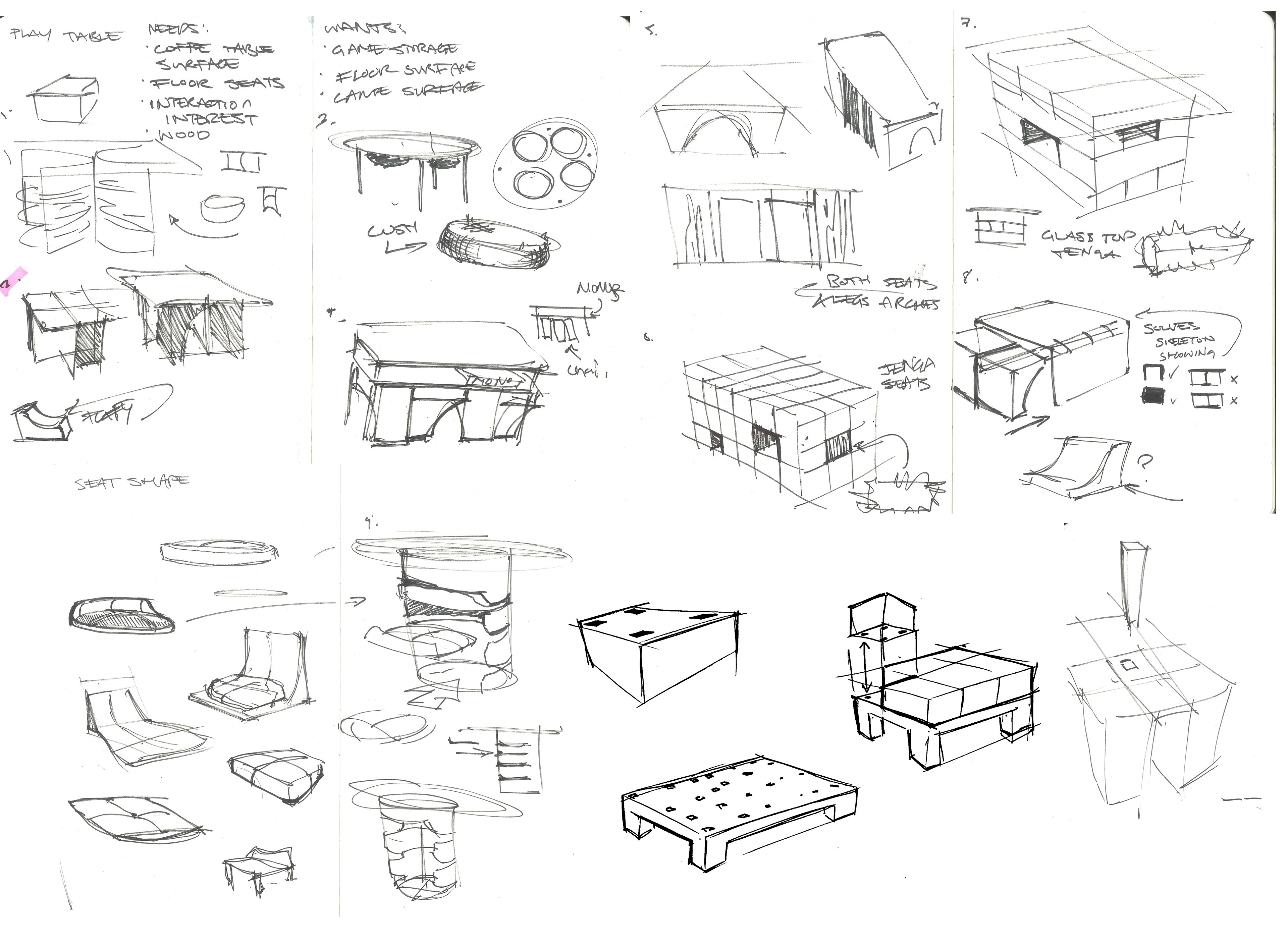

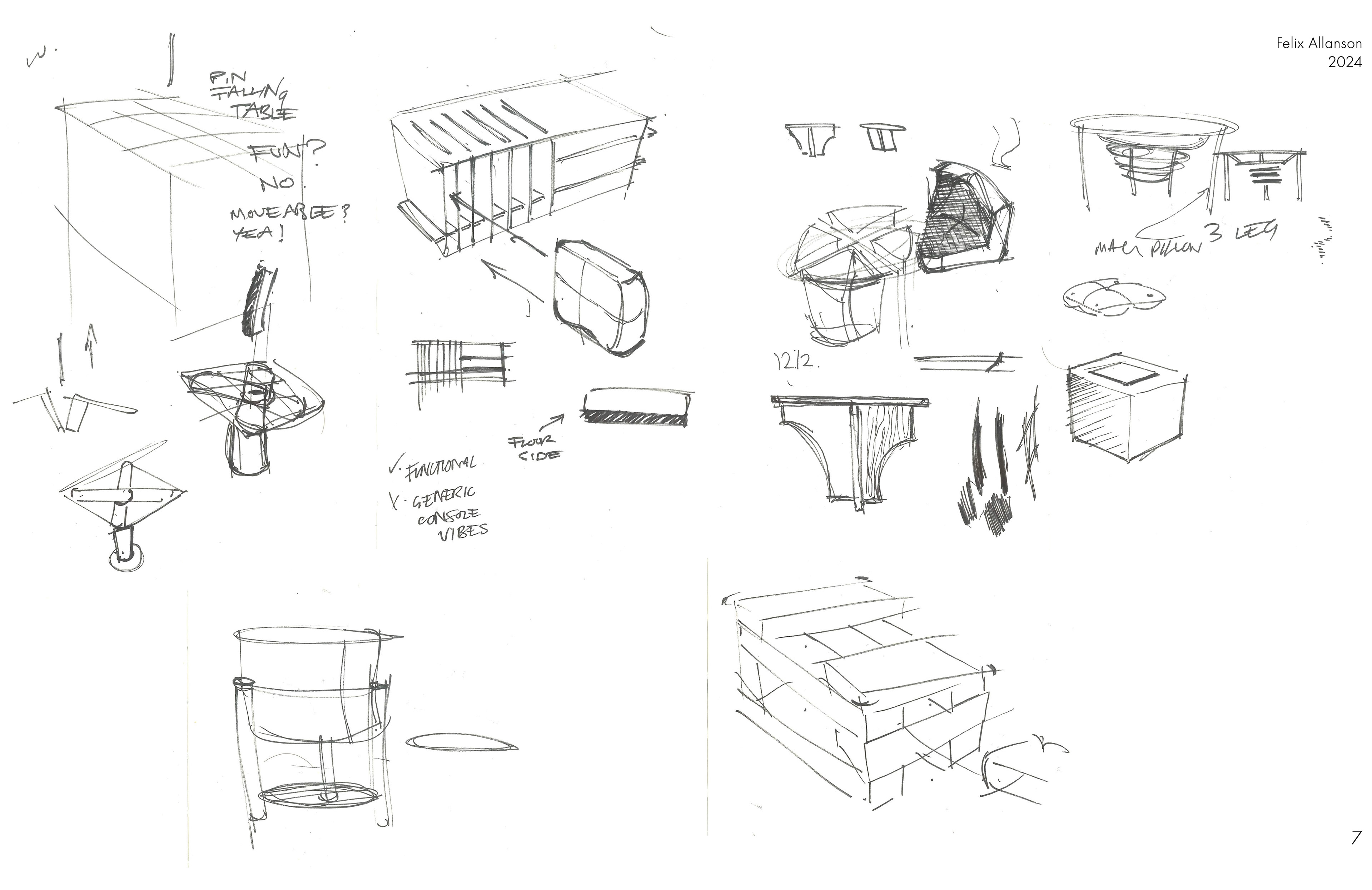

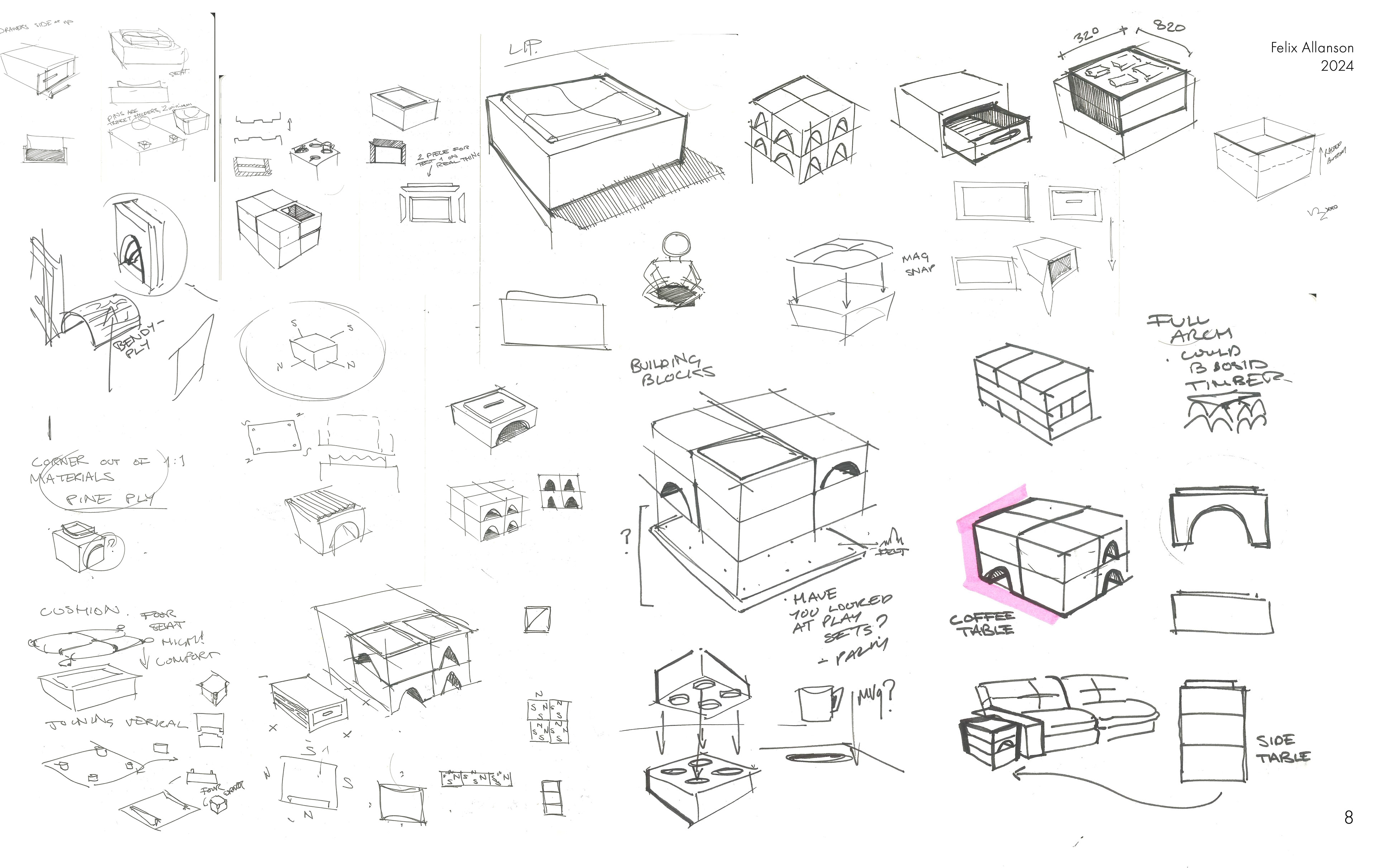

Ideation Drawings & CAD

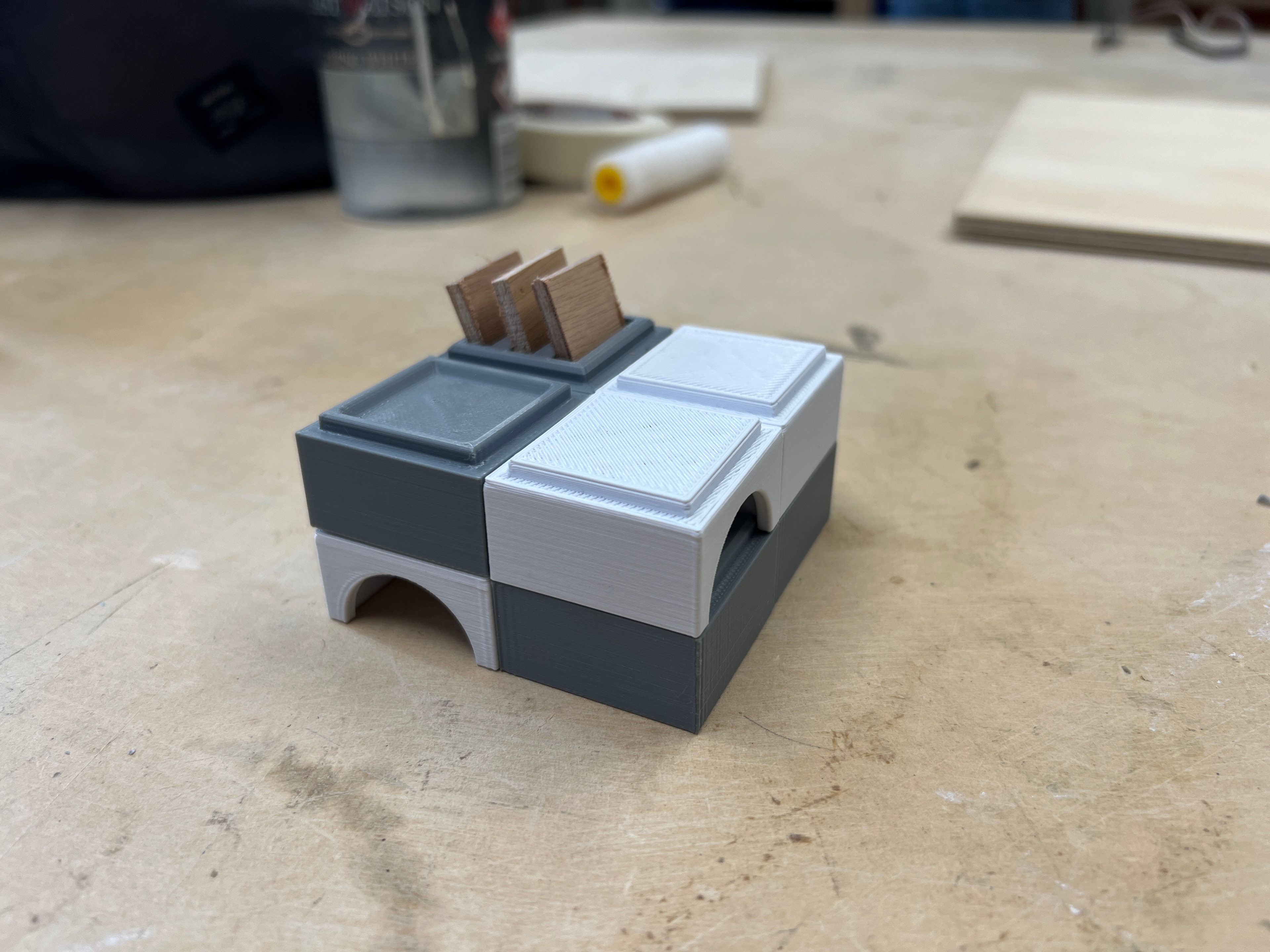

Ideation sketches were about staying open, testing forms, and exploring every possibility. I focused on optimising storage and interaction, focusing on achieving a coffee table, floor stool, and side table configurations and more where possible. Balancing the different modularities and storage methods was a great design challenge.

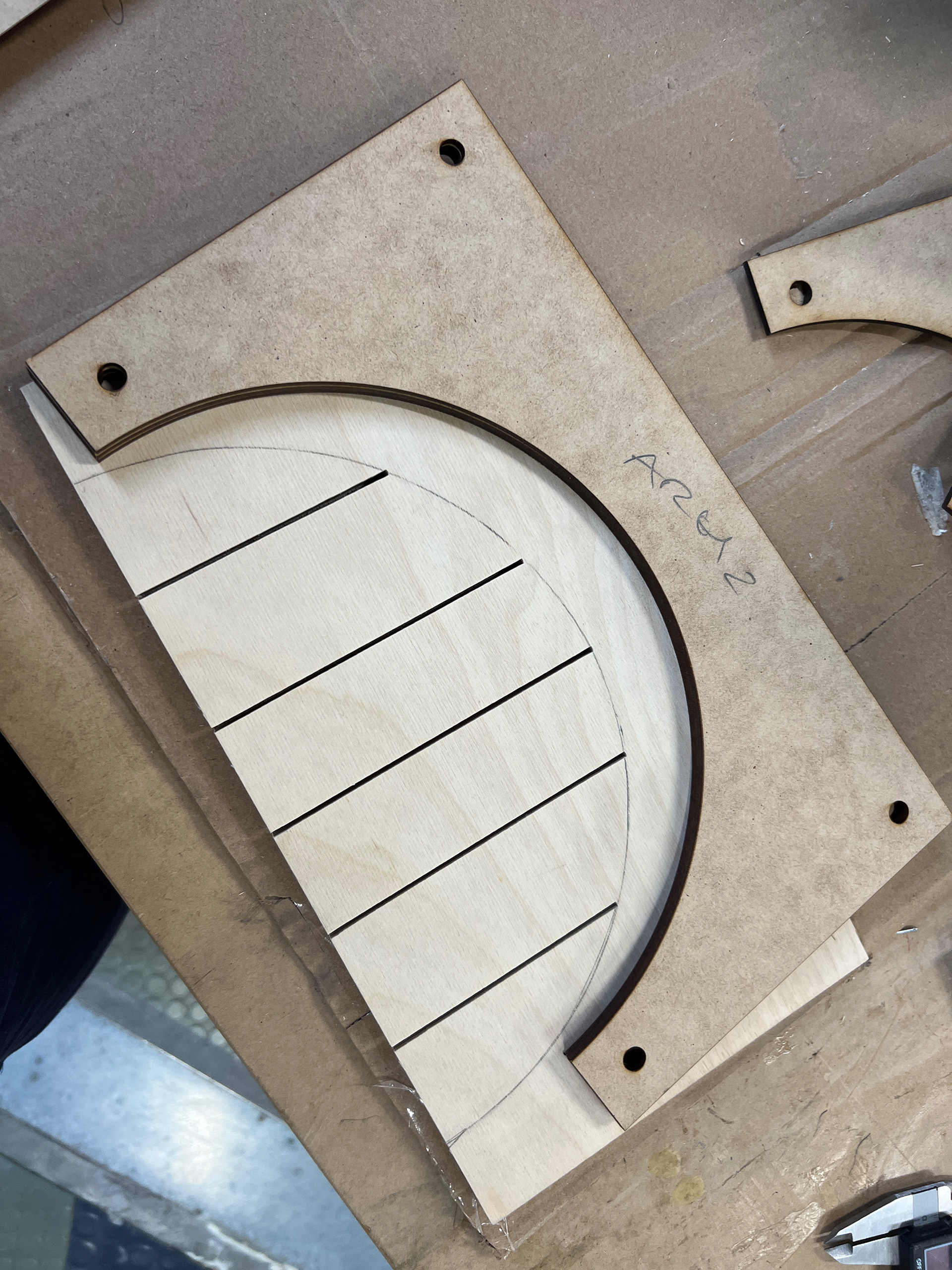

1:1 Models

Went through three iterations of the cardboard 1:1 model, optimising dimensions considering the different forms the modules would take. Tested shelf dimensions.

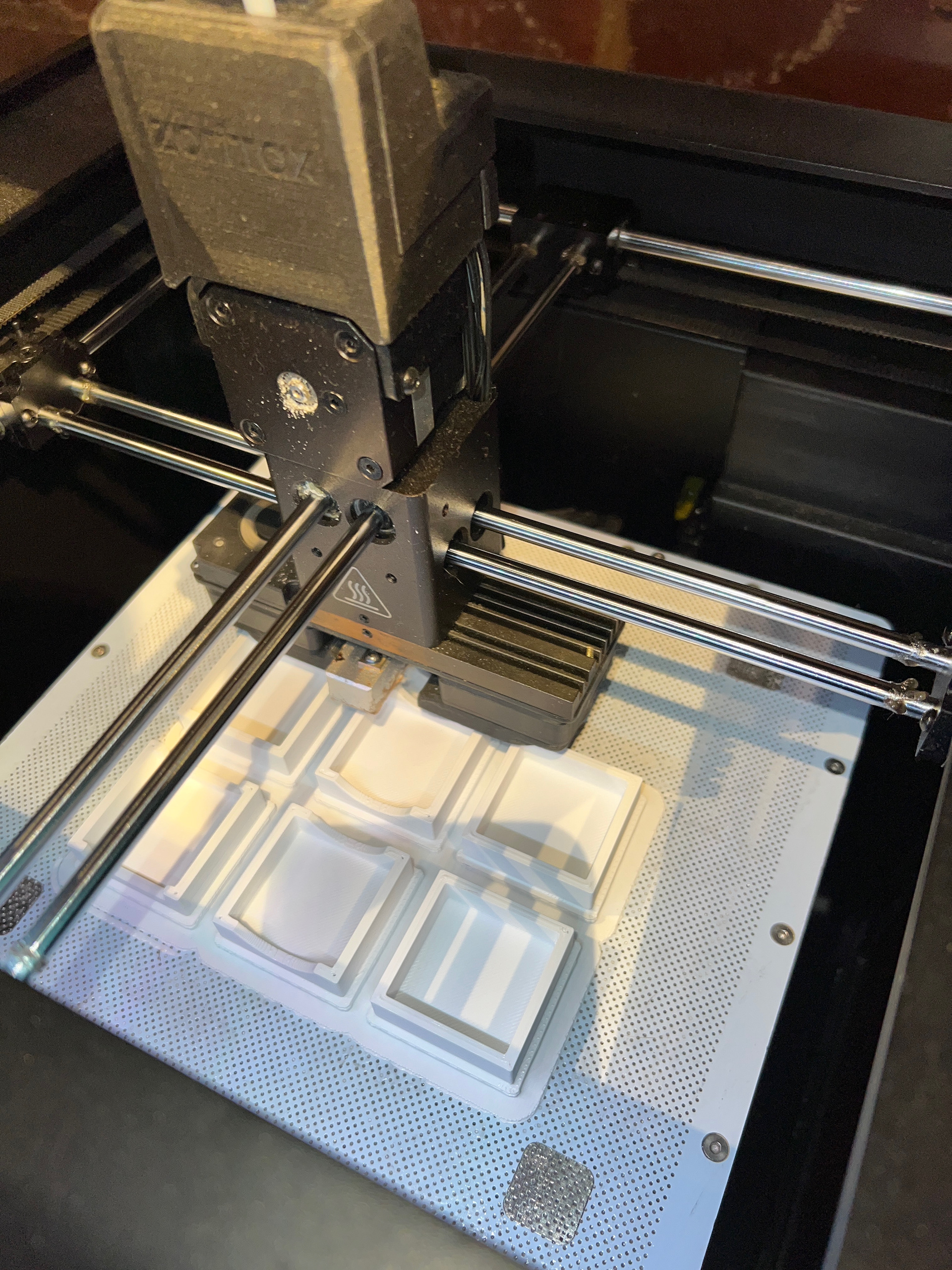

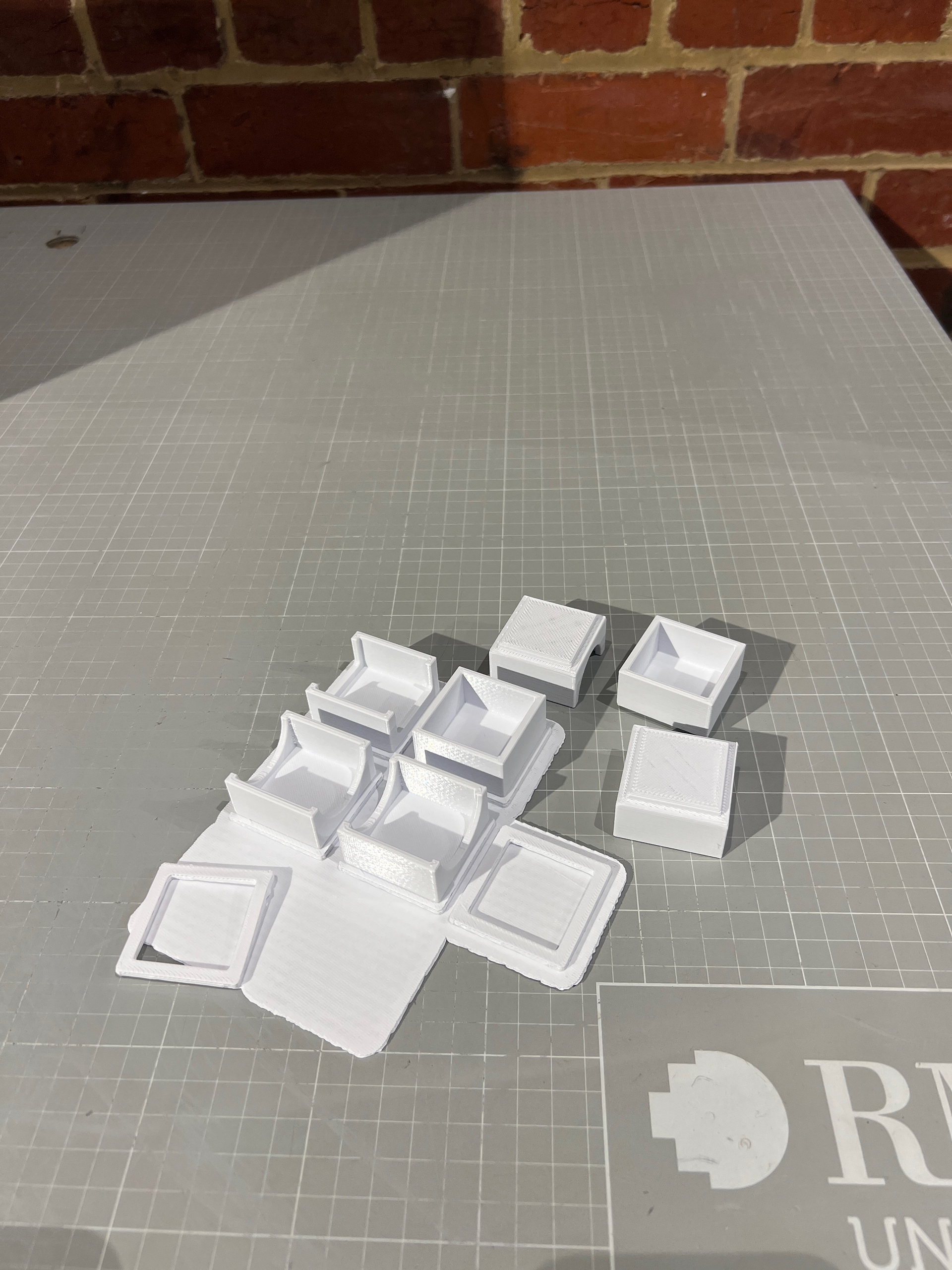

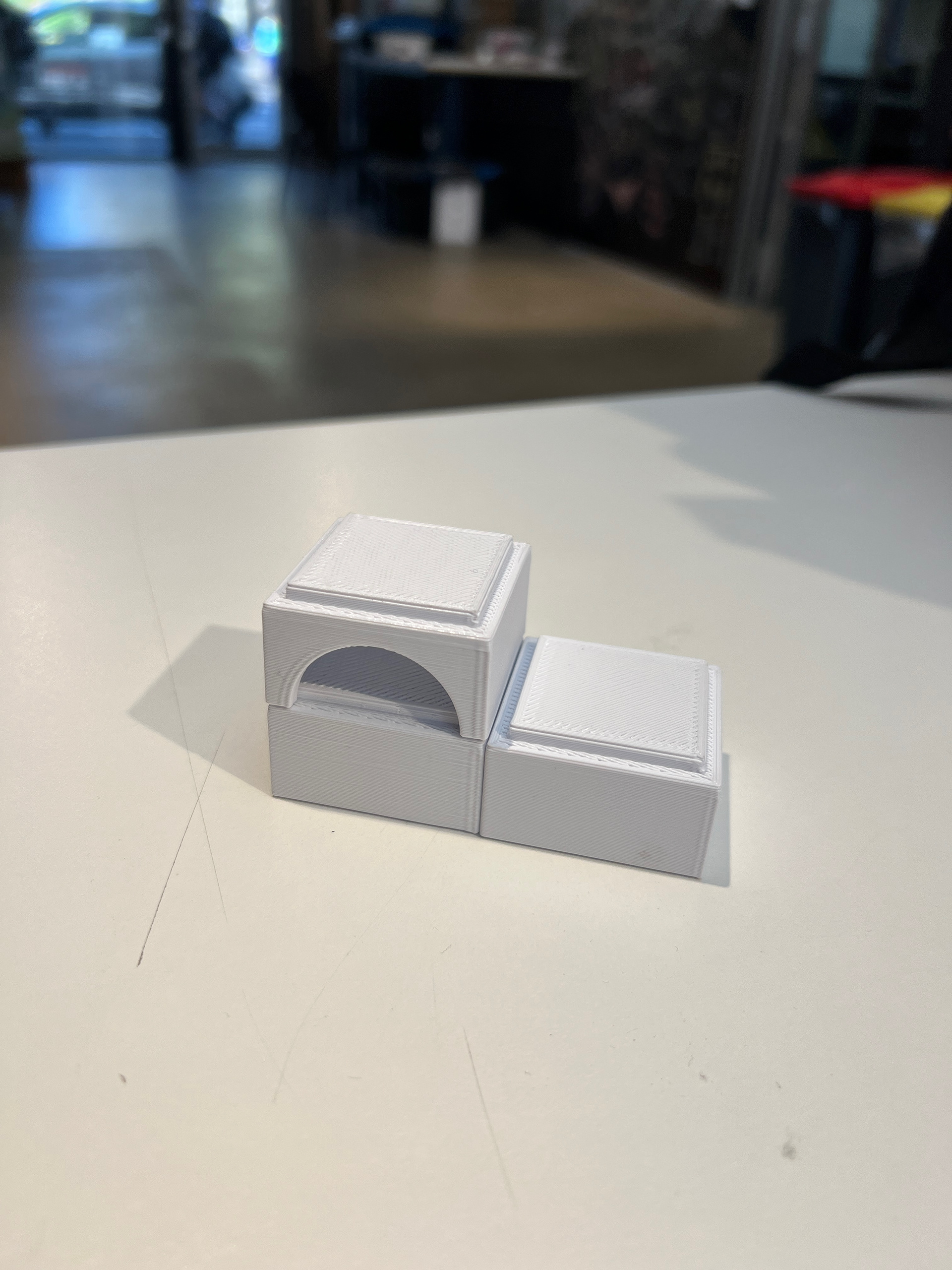

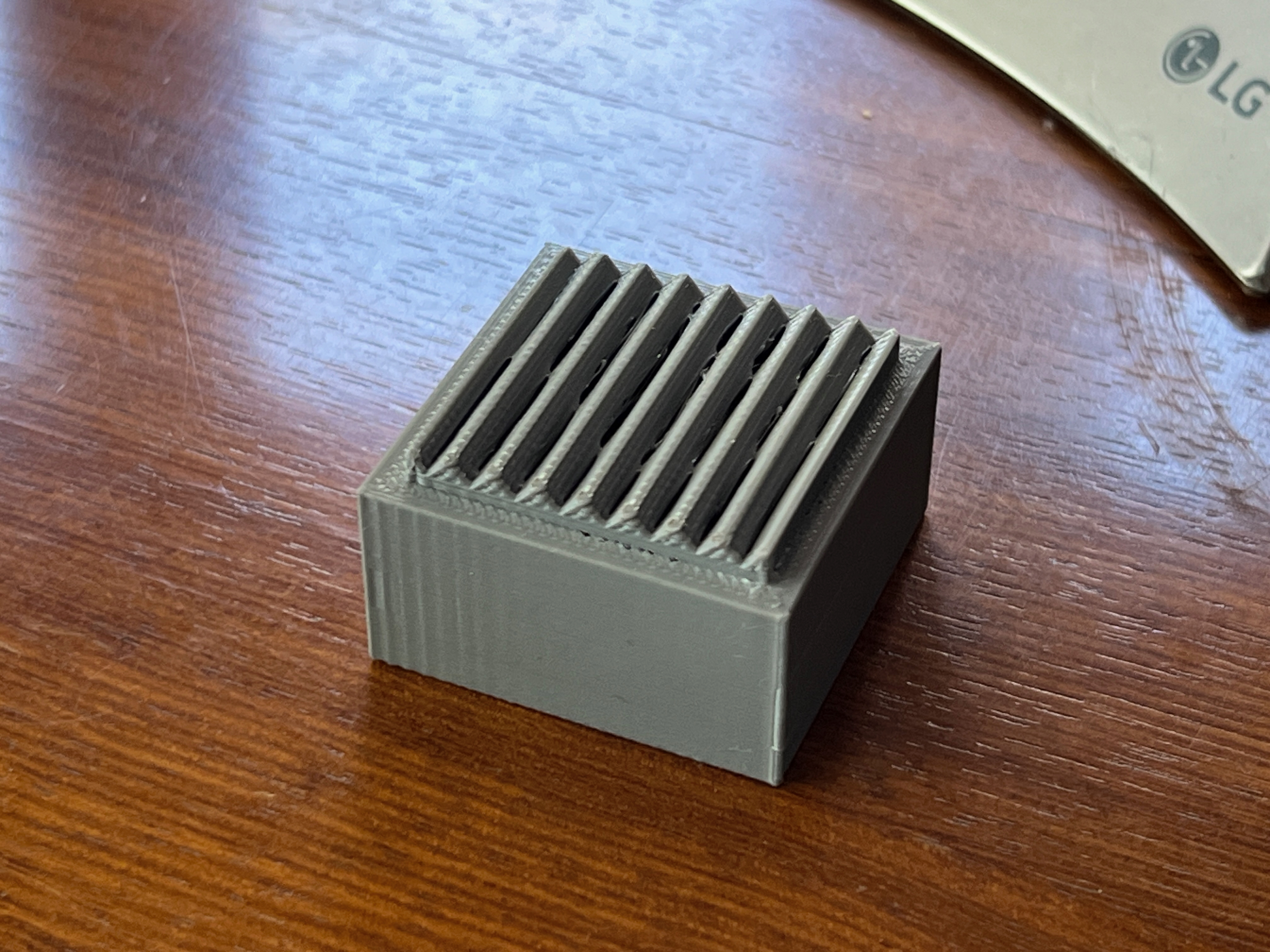

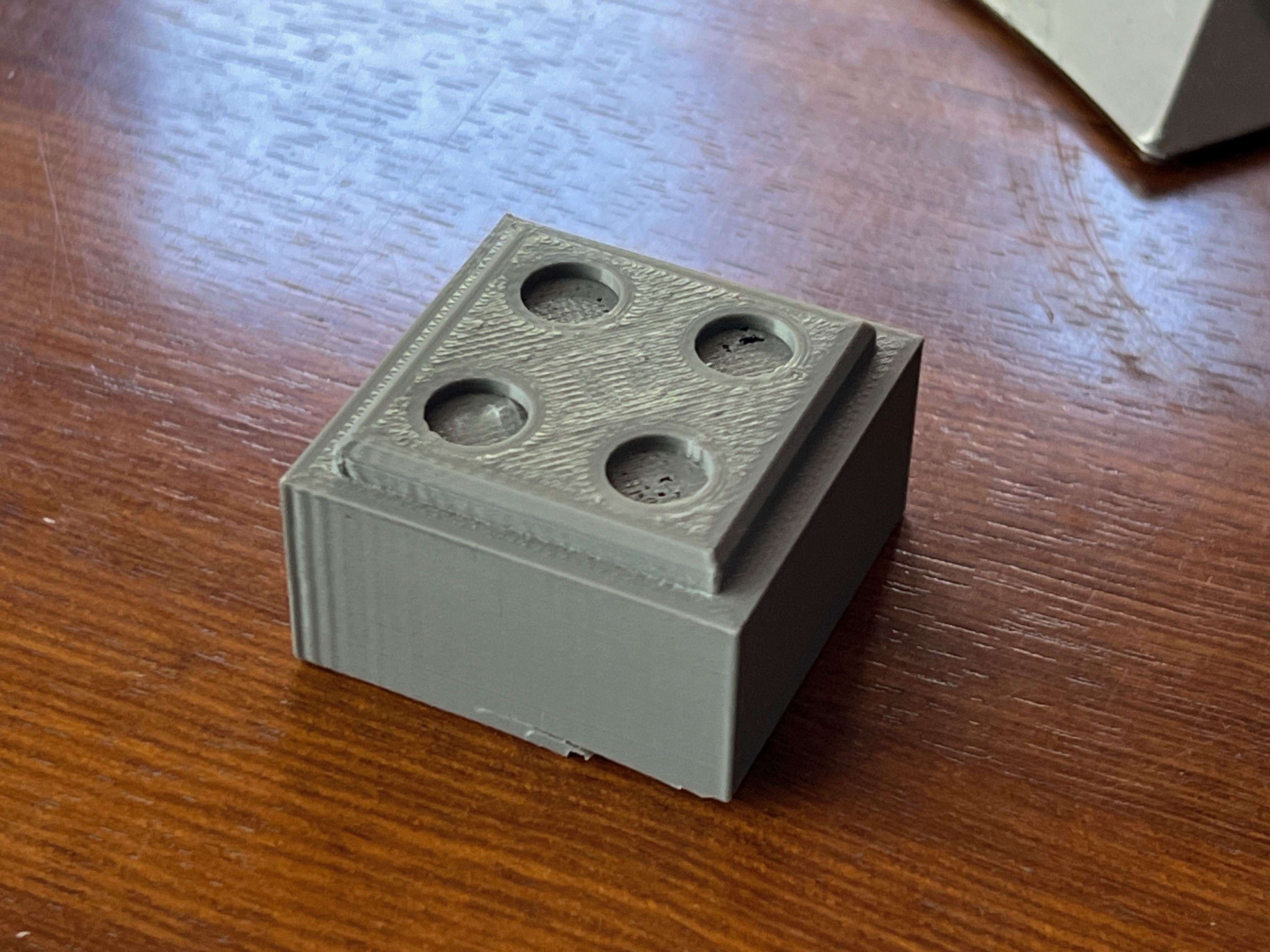

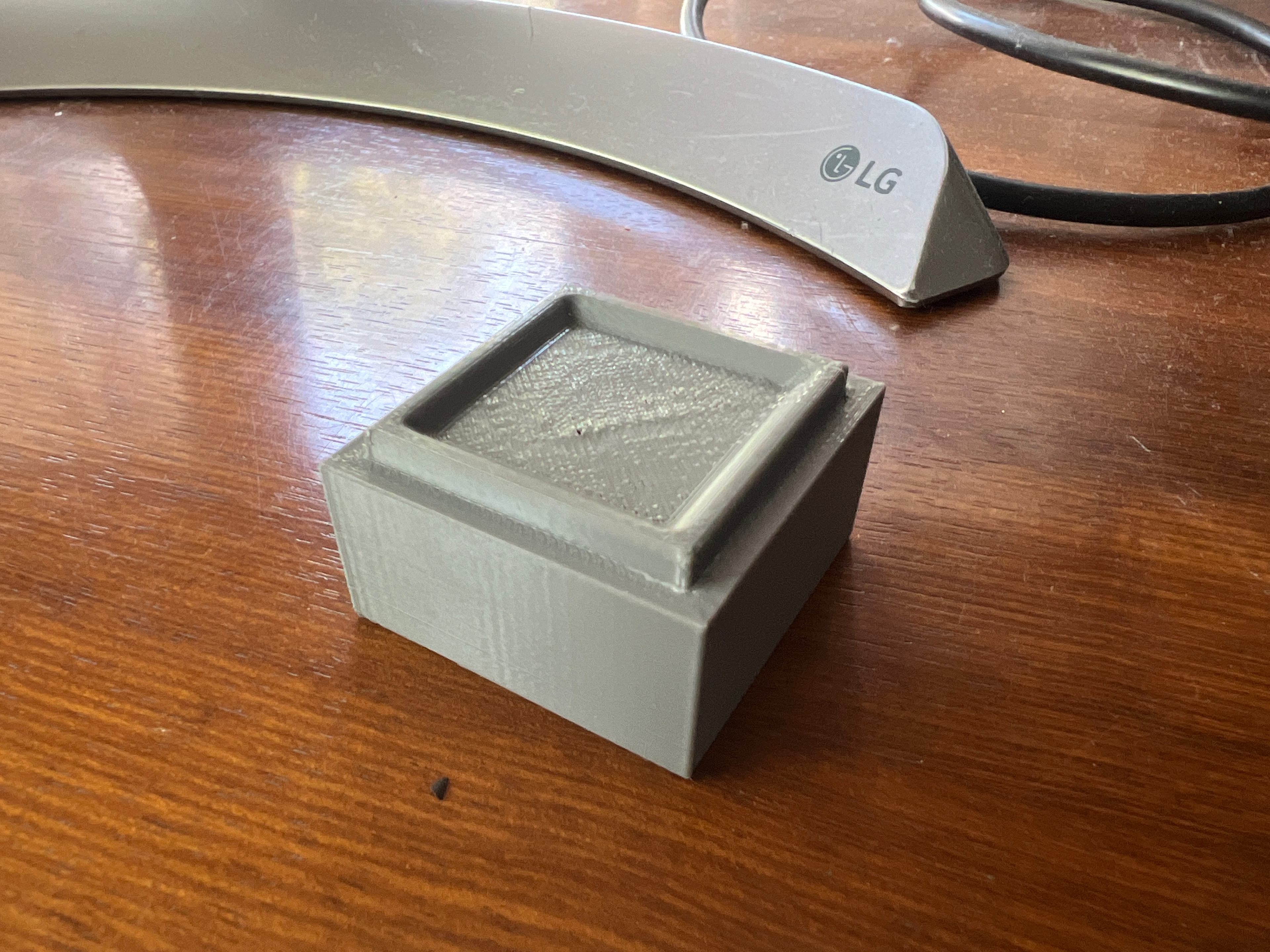

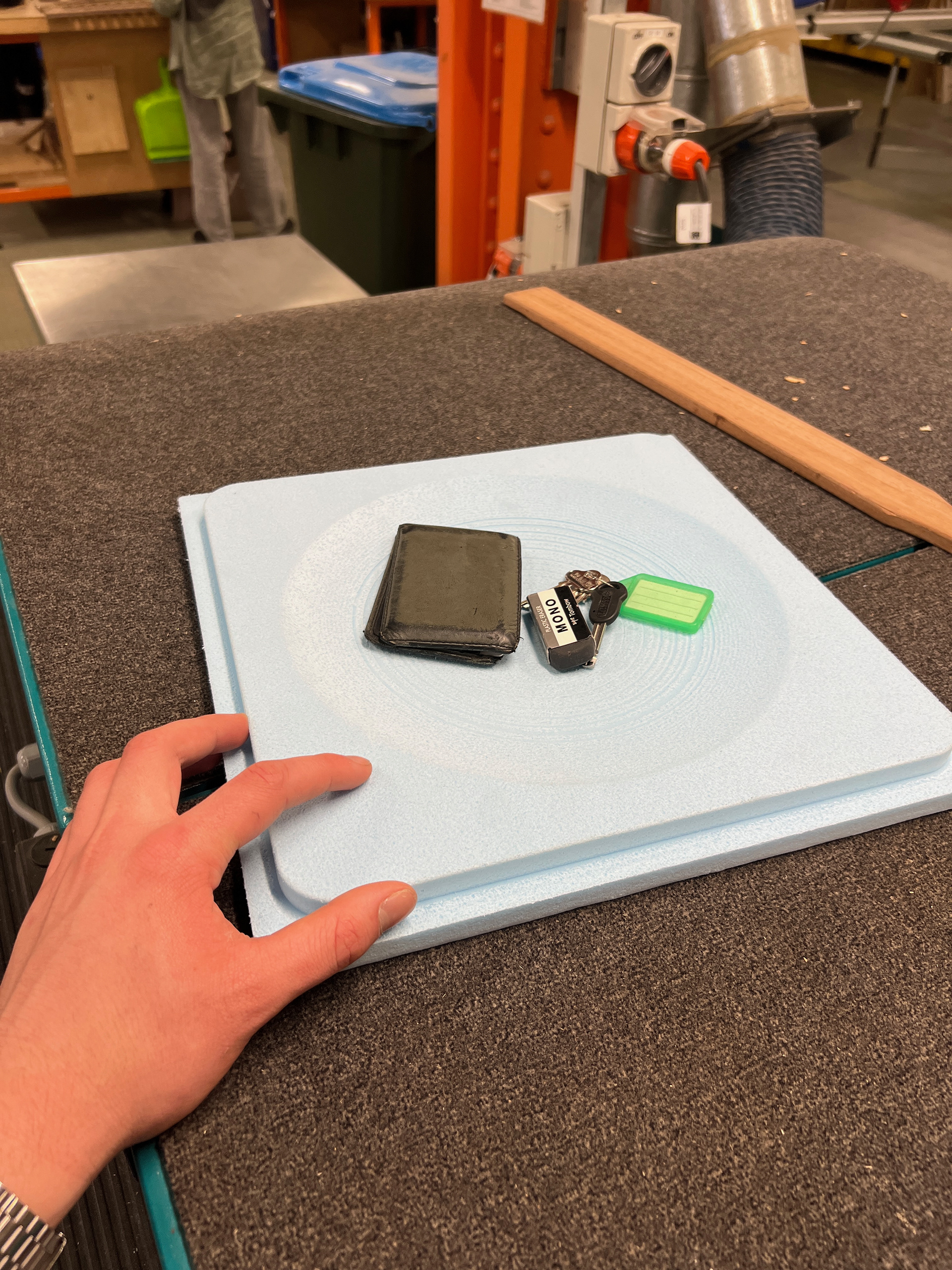

Scale Models

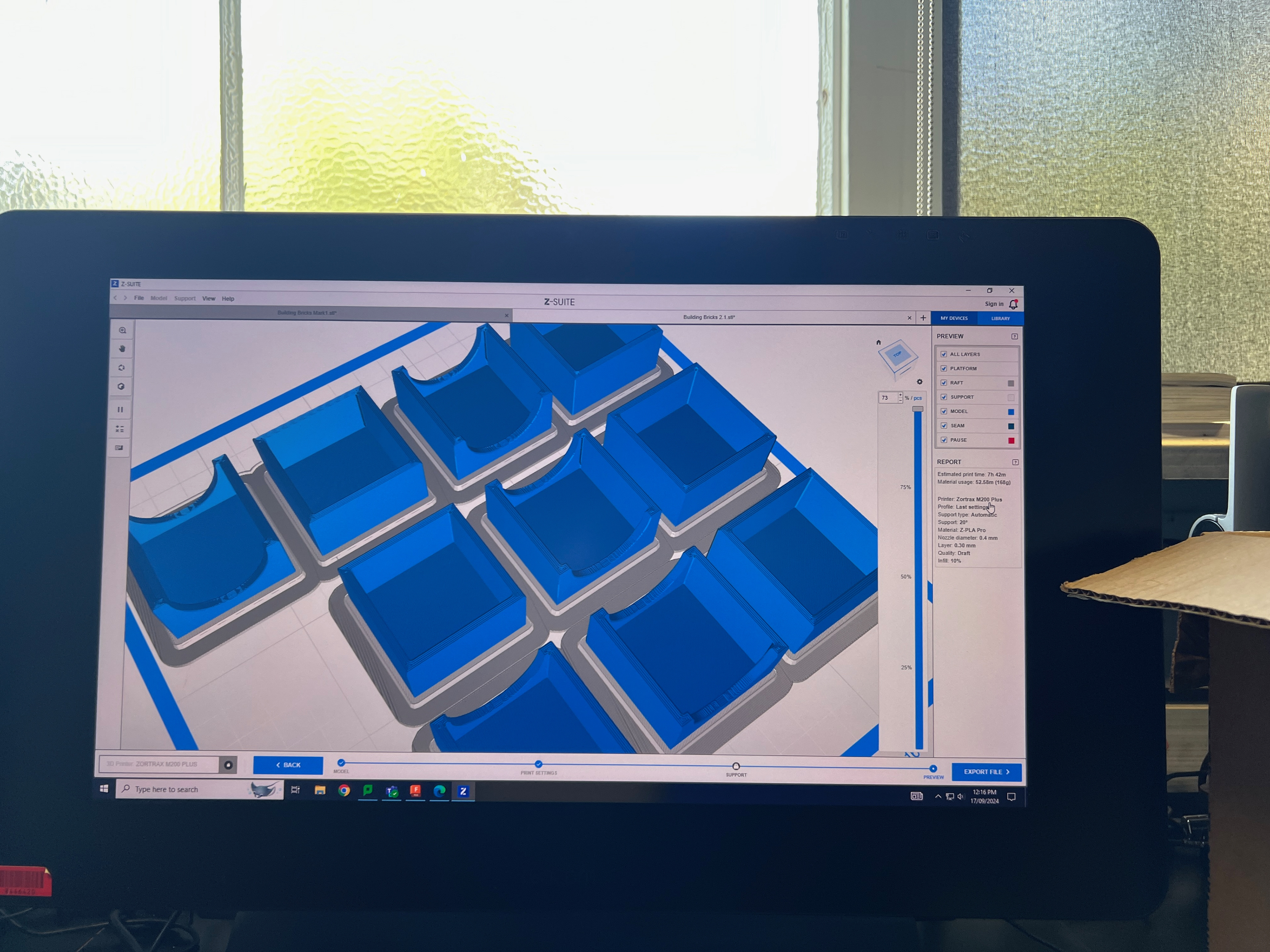

The scale model series used hot wire foam cutting and multiple 3D print iterations. I tested the modular click-fit, played with different arrangements, and made new module block designs to add more function and visual interest.

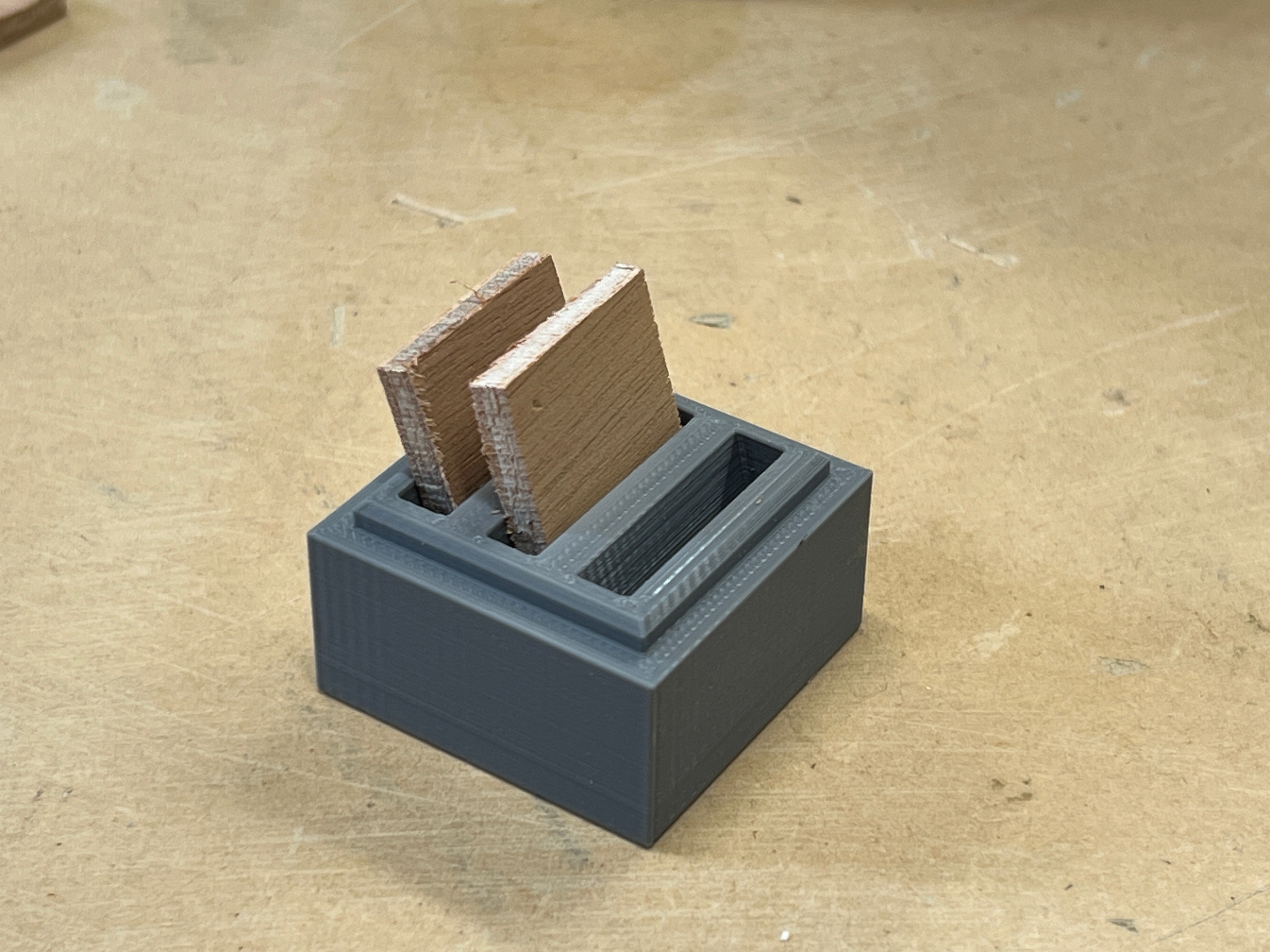

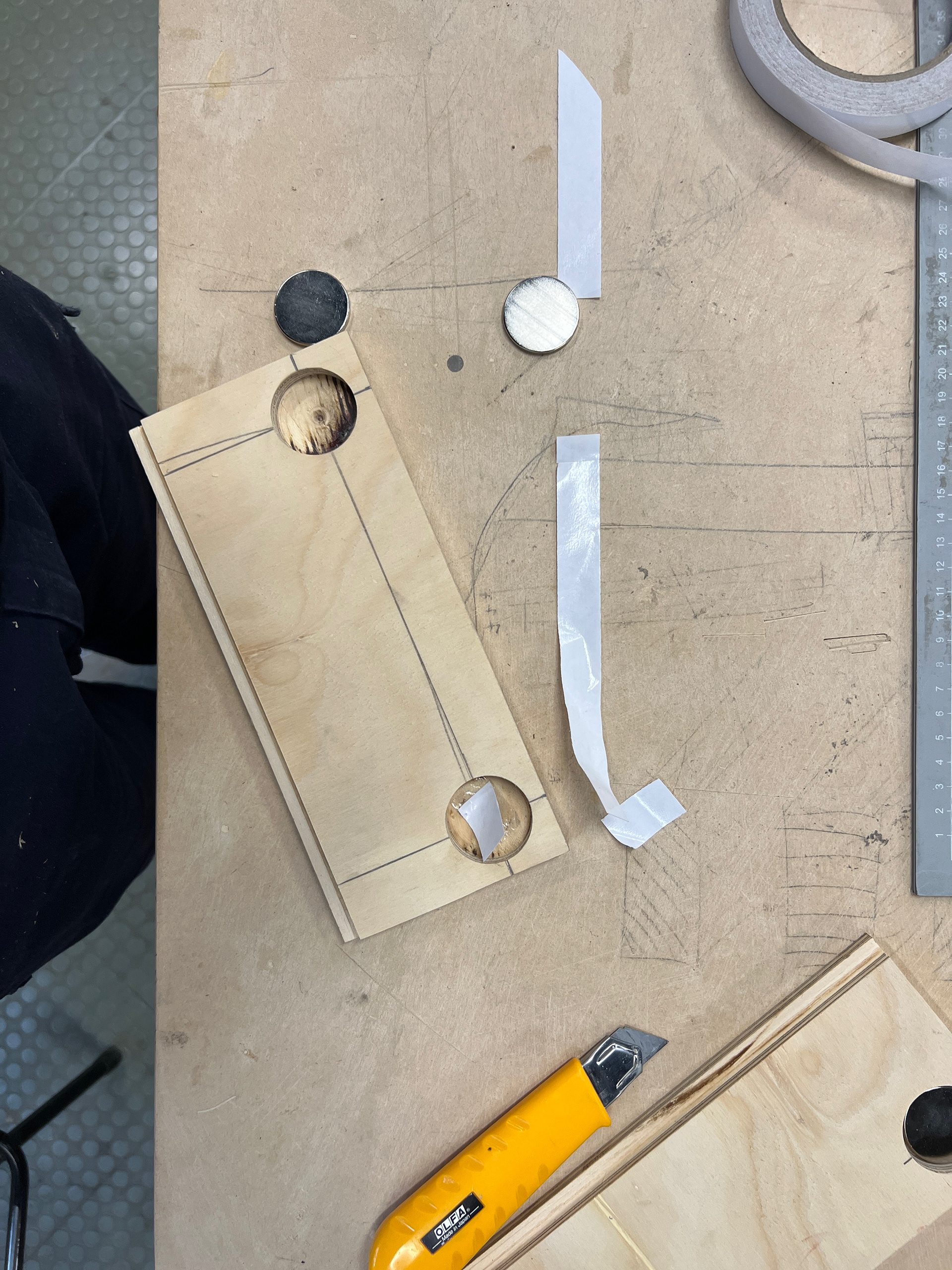

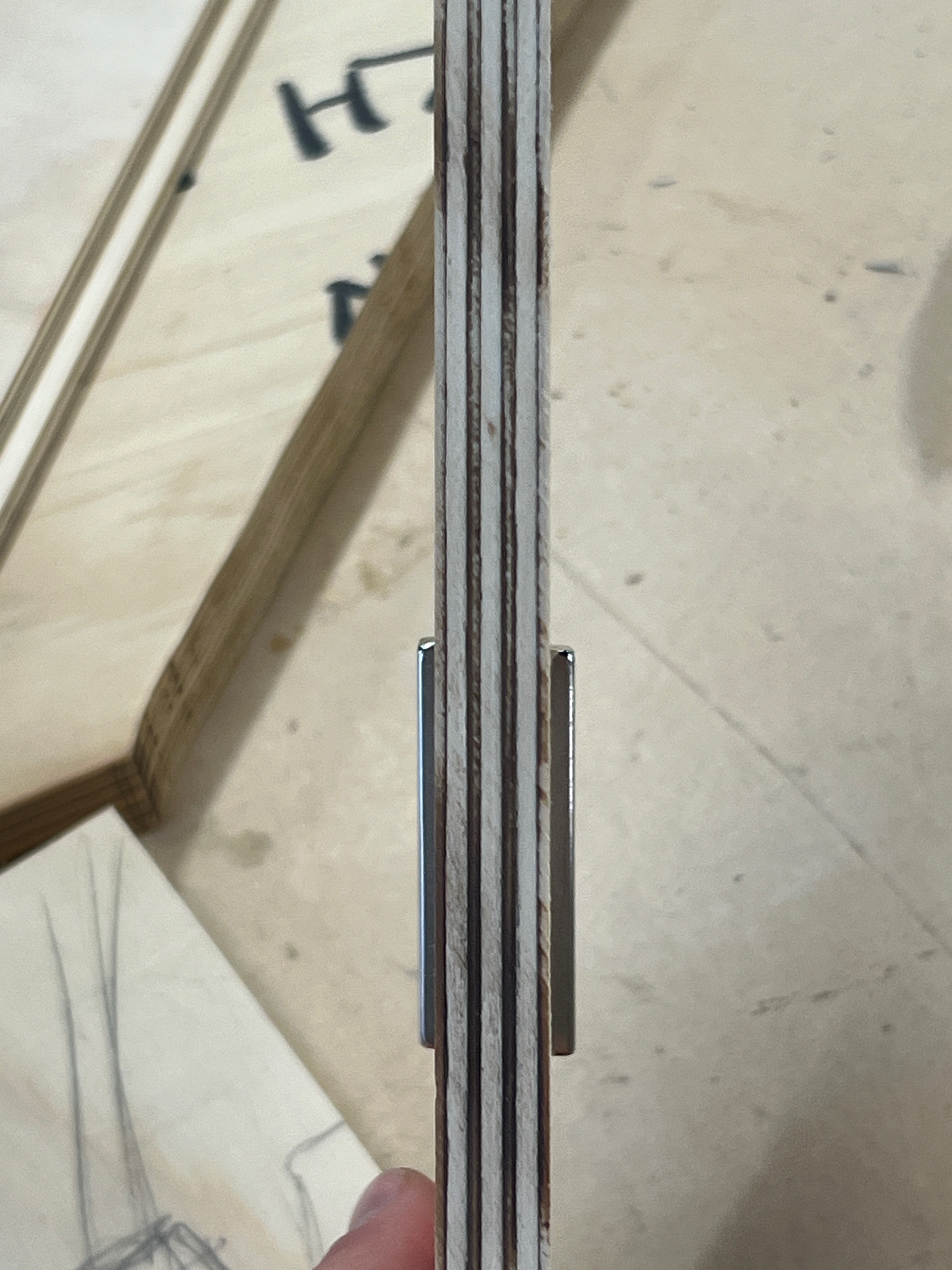

1:1 Section & Magnet Models

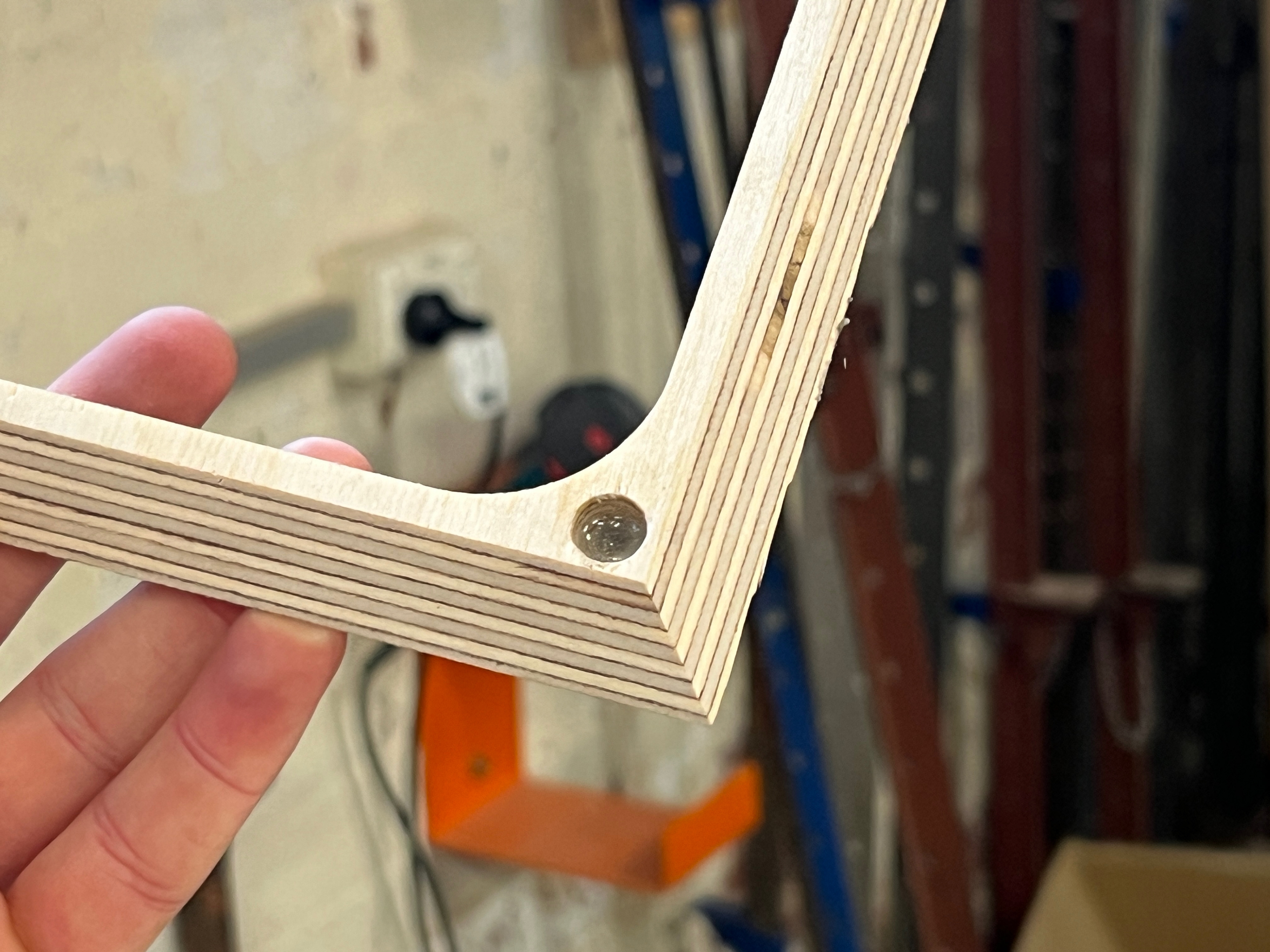

The vertical connection was solved with the LEGO like click mechanism; however, the horizontal method of security needed to be tested. The plan was to have magnets buried in the underside of the wood to provide a seamless method of connection for the module blocks. While these tests appeared successful, upon reflection, this move would not hold the blocks as securely as expected, adding usability difficulties and significant cost to the manufacturing.

Manufacturing

Final Outcome